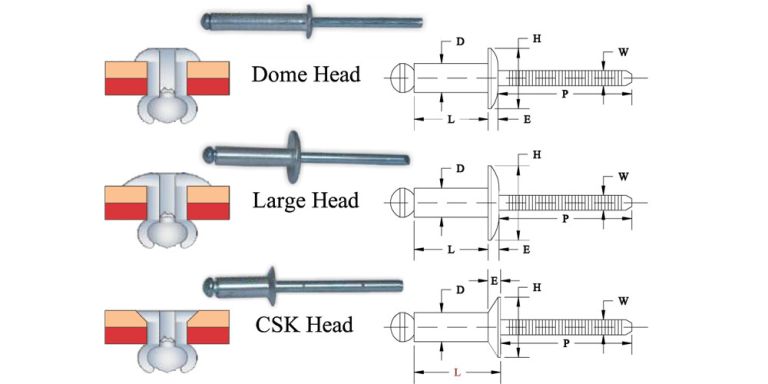

SL Fasteners Pvt. Ltd. manufacture the basic blind rivets in all sizes and styles. Open Type Blind Rivets are made as per IFI-114, DIN, and ASME standards. Different head styles are available as dome head blind rivets, CSK head Blind Rivets, and Large Flange Blind Rivets. These blind rivets are made in 3 material grades :

- Aluminium Blind Rivets

Available Grades: Aluminium 1100, 5050, 5052, 5056, 5154 - Steel Blind Rivets –

Available Grades: Low Carbon Steel - Stainless Steel Blind Rivets

Available Grades: Stainless Steel 302, 304

The various diameters and lengths of Rivets are available as per customer applications

- 2.4 mm Blind Rivet (Lengths: 4.8 mm, 6.4 mm, 8.0 mm, 9.6 mm, 12.7 mm, 15.9 mm)

- 3.2 mm Blind Rivet (Lengths: 6.4 mm, 8. o mm, 9.6 mm, 12.7 mm, 15.9 mm, 19.3 mm, 25.4 mm)

- 4.0 mm Blind Rivet (Lengths: 6.4 mm, 8.0 mm, 9.6 mm, 12.7 mm, 15.9 mm, 19.3mm, 19.3mm)

- 4.8 mm Blind Rivets (Lengths: 6.4mm, 8. o mm, 6.4 mm, 12.7 mm, 12.7 mm, 19.3 mm 31.8 mm, 31.8 mm, 50.8 mm)

- 6.4 mm, Blind Rivets ( Lengths: 9.6 mm, 12.7 mm, 15.9 mm. 19.3mm, 25.4 mm)

Apart from the above-mentioned sizes customized blind rivets are manufactured per customer drawings and various applications.

Open Type Blind Rivets

Open Type Blind Rivets

Open Type Blind Rivets

Open Type Blind Rivets

Material

- Rivet Body – Aluminium 1100, Mandrel – Steel

- Rivet Body – Aluminium 5050, Mandrel – Steel

- Rivet Body – Aluminium 5052, Mandrel – Steel

- Rivet Body – Aluminium 5154, Mandrel – Steel

- Rivet Body – Aluminium 5056, Mandrel – Steel

- Rivet Body – Steel, Mandrel – Steel

- Rivet Body – Stainless Steel, Mandrel – Stainless Steel

- Rivet Body – Copper, Mandrel – Steel

Key Features

- Available in a range of size and materials.

- Versatile for general fastening needs.

- Strong, low cost fastenings.

- Ideal for wide range of applications.

| Open Type Blind Rivet | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nom Rivet Size (Inch) | Nom Rivet Size (mm) | Rivet Code | Hole Dia | Domed Head Dia | Head Height | Large Head Dia | Head Height | CSK 120°±2° Head Dia | Head Height | Mandrel Dia | Mandrel Protrusion | Domed Head Grip Range | CSK 120° Head Grip Range | |||||

| D | L | D | L | H | E | H | E | H | E | W | P | |||||||

| -0.2 | Max. | -0.2 | Max. | Min.~ Max. | Min. | Max. | Max. | Min. | Max. | Max. | Min. | Max. | Max. | Nom | Min. | Min.~ Max. | Min.~ Max. | |

| 3/32 | 3/16 | 2.4 | 4.8 | 3-1 | 2.5~2.6 | 4.5 | 5.0 | 0.8 | 6.8 | 7.4 | 1.0 | 4.0 | 4.7 | 0.7 | 1.4 | 27.0 | 0.5 ~ 1.0 | 0.5 ~ 1.0 |

| 1/4 | 6.4 | 3-2 | 2.5~2.6 | 4.5 | 5.0 | 0.8 | 6.8 | 7.4 | 1.0 | 4.0 | 4.7 | 0.7 | 1.4 | 27.0 | 0.5 ~ 1.6 | 0.5 ~ 1.6 | ||

| 5/16 | 8.0 | 3-3 | 2.5~2.6 | 4.5 | 5.0 | 0.8 | 6.8 | 7.4 | 1.0 | 4.0 | 4.7 | 0.7 | 1.4 | 27.0 | 1.6 ~ 3.2 | 1.6 ~ 3.2 | ||

| 3/8 | 9.6 | 3-4 | 2.5~2.6 | 4.5 | 5.0 | 0.8 | 6.8 | 7.4 | 1.0 | 4.0 | 4.7 | 0.7 | 1.4 | 27.0 | 3.2 ~ 4.8 | 3.2 ~ 4.8 | ||

| 1/2 | 12.7 | 3-5 | 2.5~2.6 | 4.5 | 5.0 | 0.8 | 6.8 | 7.4 | 1.0 | 4.0 | 4.7 | 0.7 | 1.4 | 27.0 | 4.8 ~ 6.4 | 4.8 ~ 6.4 | ||

| 5/8 | 15.9 | 3-6 | 2.5~2.6 | 4.5 | 5.0 | 0.8 | 6.8 | 7.4 | 1.0 | 4.0 | 4.7 | 0.7 | 1.4 | 27.0 | 6.4 ~ 9.6 | 6.4 ~ 9.6 | ||

| 1/8 | 1/4 | 3.2 | 6.4 | 4-1 | 3.3~3.4 | 6.0 | 6.6 | 1.0 | 9.1 | 9.9 | 1.6 | 5.3 | 5.9 | 0.8 | 1.9 | 27.0 | 0.5 ~ 1.6 | 0.5 ~ 1.6 |

| 5/16 | 8.0 | 4-2 | 3.3~3.4 | 6.0 | 6.6 | 1.0 | 9.1 | 9.9 | 1.6 | 5.3 | 5.9 | 0.8 | 1.9 | 27.0 | 1.6 ~ 3.2 | 1.6 ~ 3.2 | ||

| 3/8 | 9.6 | 4-3 | 3.3~3.4 | 6.0 | 6.6 | 1.0 | 9.1 | 9.9 | 1.6 | 5.3 | 5.9 | 0.8 | 1.9 | 27.0 | 3.2 ~ 4.8 | 3.2 ~ 4.8 | ||

| 1/2 | 12.7 | 4-4 | 3.3~3.4 | 6.0 | 6.6 | 1.0 | 9.1 | 9.9 | 1.6 | 5.3 | 5.9 | 0.8 | 1.9 | 27.0 | 4.8 ~ 6.4 | 4.8 ~ 6.4 | ||

| 5/8 | 15.9 | 4-5 | 3.3~3.4 | 6.0 | 6.6 | 1.0 | 9.1 | 9.9 | 1.6 | 5.3 | 5.9 | 0.8 | 1.9 | 27.0 | 6.4 ~ 9.6 | 6.4 ~ 9.6 | ||

| 3/4 | 19.3 | 4-6 | 3.3~3.4 | 6.0 | 6.6 | 1.0 | 9.1 | 9.9 | 1.6 | 5.3 | 5.9 | 0.8 | 1.9 | 27.0 | 9.6 ~ 12.7 | 9.6 ~ 12.7 | ||

| 1.0 | 25.4 | 4-7 | 3.3~3.4 | 6.0 | 6.6 | 1.0 | 9.1 | 9.9 | 1.6 | 5.3 | 5.9 | 0.8 | 1.9 | 27.0 | 16.0 ~ 19.0 | 16.0 ~ 19.0 | ||

| 5/32 | 1/4 | 4.0 | 6.4 | 5-1 | 4.1~4.2 | 7.5 | 8.3 | 1.27 | 11.3 | 12.4 | 1.9 | 6.8 | 7.5 | 1.0 | 2.4 | 27.0 | 0.5 ~ 1.6 | 0.5 ~ 1.6 |

| 5/16 | 8.0 | 5-2 | 4.1~4.2 | 7.5 | 8.3 | 1.27 | 11.3 | 12.4 | 1.9 | 6.8 | 7.5 | 1.0 | 2.4 | 27.0 | 1.6 ~ 3.2 | 1.6 ~ 3.2 | ||

| 3/8 | 9.6 | 5-3 | 4.1~4.2 | 7.5 | 8.3 | 1.27 | 11.3 | 12.4 | 1.9 | 6.8 | 7.5 | 1.0 | 2.4 | 27.0 | 3.2 ~ 4.8 | 3.2 ~ 4.8 | ||

| 1/2 | 12.7 | 5-4 | 4.1~4.2 | 7.5 | 8.3 | 1.27 | 11.3 | 12.4 | 1.9 | 6.8 | 7.5 | 1.0 | 2.4 | 27.0 | 4.8 ~ 6.4 | 4.8 ~ 6.4 | ||

| 5/8 | 15.9 | 5-5 | 4.1~4.2 | 7.5 | 8.3 | 1.27 | 11.3 | 12.4 | 1.9 | 6.8 | 7.5 | 1.0 | 2.4 | 27.0 | 6.4 ~ 9.6 | 6.4 ~ 9.6 | ||

| 3/4 | 19.3 | 5-6 | 4.1~4.2 | 7.5 | 8.3 | 1.27 | 11.3 | 12.4 | 1.9 | 6.8 | 7.5 | 1.0 | 2.4 | 27.0 | 9.6 ~ 12.7 | 9.6 ~ 12.7 | ||

| 1.0 | 25.4 | 5-7 | 4.1~4.2 | 7.5 | 8.3 | 1.27 | 11.3 | 12.4 | 1.9 | 6.8 | 7.5 | 1.0 | 2.4 | 27.0 | 16.0 ~ 19.0 | 16.0 ~ 19.0 | ||

| 3/16 | 1/4 | 4.8 | 6.4 | 6-1 | 4.9~5.0 | 9.0 | 10.0 | 1.52 | 15.2 | 16.5 | 2.3 | 8.5 | 9.2 | 1.3 | 2.8 | 27.0 | 0.5 ~ 1.6 | 0.5 ~ 1.6 |

| 5/16 | 8.0 | 6-2 | 4.9~5.0 | 9.0 | 10.0 | 1.52 | 15.2 | 16.5 | 2.3 | 8.5 | 9.2 | 1.3 | 2.8 | 27.0 | 1.6 ~ 3.2 | 1.6 ~ 3.2 | ||

| 3/8 | 9.6 | 6-3 | 4.9~5.0 | 9.0 | 10.0 | 1.52 | 15.2 | 16.5 | 2.3 | 8.5 | 9.2 | 1.3 | 2.8 | 27.0 | 3.2 ~ 4.8 | 3.2 ~ 4.8 | ||

| 1/2 | 12.7 | 6-4 | 4.9~5.0 | 9.0 | 10.0 | 1.52 | 15.2 | 16.5 | 2.3 | 8.5 | 9.2 | 1.3 | 2.8 | 27.0 | 4.8 ~ 6.4 | 4.8 ~ 6.4 | ||

| 5/8 | 15.9 | 6-5 | 4.9~5.0 | 9.0 | 10.0 | 1.52 | 15.2 | 16.5 | 2.3 | 8.5 | 9.2 | 1.3 | 2.8 | 27.0 | 6.4 ~ 9.6 | 6.4 ~ 9.6 | ||

| 3/4 | 19.3 | 6-6 | 4.9~5.0 | 9.0 | 10.0 | 1.52 | 15.2 | 16.5 | 2.3 | 8.5 | 9.2 | 1.3 | 2.8 | 27.0 | 9.6 ~ 12.7 | 9.6 ~ 12.7 | ||

| 1.0 | 25.4 | 6-7 | 4.9~5.0 | 9.0 | 10.0 | 1.52 | 15.2 | 16.5 | 2.3 | 8.5 | 9.2 | 1.3 | 2.8 | 27.0 | 16.0 ~ 19.0 | 16.0 ~ 19.0 | ||

| 1¼ | 31.8 | 6-8 | 4.9~5.0 | 9.0 | 10.0 | 1.52 | 15.2 | 16.5 | 2.3 | 8.5 | 9.2 | 1.3 | 2.8 | 27.0 | 22.4 ~ 25.4 | 22.4 ~ 25.4 | ||

| 1½ | 38.1 | 6-9 | 4.9~5.0 | 9.0 | 10.0 | 1.52 | 15.2 | 16.5 | 2.3 | 8.5 | 9.2 | 1.3 | 2.8 | 27.0 | 28.6 ~ 31.8 | 28.6 ~ 31.8 | ||

| 2.0 | 50.8 | 6-10 | 4.9~5.0 | 9.0 | 10.0 | 1.52 | 15.2 | 16.5 | 2.3 | 8.5 | 9.2 | 1.3 | 2.8 | 27.0 | 31.8 ~ 35.0 | 31.8 ~ 35.0 | ||

| 1/4 | 3/8 | 6.4 | 9.6 | 7-1 | 6.5~6.6 | 12.0 | 13.3 | 2.0 | 18.2 | 19.8 | 2.7 | 11.6 | 12.3 | 1.5 | 3.8 | 31.7 | 3.2 ~ 4.8 | 3.2 ~ 4.8 |

| 1/2 | 12.7 | 7-2 | 6.5~6.6 | 12.0 | 13.3 | 2.0 | 18.2 | 19.8 | 2.7 | 11.6 | 12.3 | 1.5 | 3.8 | 31.7 | 4.8 ~ 6.4 | 4.8 ~ 6.4 | ||

| 5/8 | 15.9 | 7-3 | 6.5~6.6 | 12.0 | 13.3 | 2.0 | 18.2 | 19.8 | 2.7 | 11.6 | 12.3 | 1.5 | 3.8 | 31.7 | 6.4 ~ 9.6 | 6.4 ~ 9.6 | ||

| 3/4 | 19.3 | 7-4 | 6.5~6.6 | 12.0 | 13.3 | 2.0 | 18.2 | 19.8 | 2.7 | 11.6 | 12.3 | 1.5 | 3.8 | 31.7 | 9.6 ~ 12.7 | 9.6 ~ 12.7 | ||

| 1.0 | 25.4 | 7-5 | 6.5~6.6 | 12.0 | 13.3 | 2.0 | 18.2 | 19.8 | 2.7 | 11.6 | 12.3 | 1.5 | 3.8 | 31.7 | 16.0 ~ 19.0 | 16.0 ~ 19.0 | ||